- professional results

- simple processing

- good face coat

- usable as backup coat too

- Suited for aluminium up to bronze

Description

HYDRACAST™ Tradition was designed to have the rheological characteristics and the ability to reproduce the fine details required for this use (no sedimentation, no slumping / flowing). This formulation is intended for making the contact layer. It can also be used mixed with fireclay (chamotte) to fill a mould. The caster can therefore create moulds that are 15 cm to 2.5 m high

Technical data

|

% of water used

|

|

add 40 to 42% water

|

|

mixing time

|

[Min]

|

4

|

|

Working / Casting time

|

[Min]

|

12-15

|

|

Setting time

|

[Min]

|

15-20 |

|

Liquid density

|

|

1.75

|

|

Weight per liter of slip:

|

1750 g

|

1220 g powder /

530 g water

|

|

Expansion 2 hours after setting time

|

|

max 0,30%

|

|

Mould preparation

|

|

Application of the Hydracast Tradition contact layer is followed by a reinforcement layer which can be Hydracast and Fireclay or another material.

|

Procedure for the Lost Wax process

The recommended plaster to water ratio is 100 parts of plaster for 40 to 42 parts of water. This ratio can be changed to precisely fit your application.

a) Mixing the plaster in water is the most important step in making a mould and could heavily impact resistance, hardness and absorption properties if performed incorrectly. For optimum quality, vacuum mixing is recommended.

Always ensure the following points:

1. Plaster and water are precisely weighed.

2. All equipment is clean.

3. The mixing cycle is adhered to.

b) Spraying / pouring. Apply by casting or spraying manually or mechanically (spray gun) immediately after mixing. Make sure that the mixture does not become too thick or too hard.

c) Plaster setting. Do not handle plaster containing wax model until it has reached its setting time to avoid any defects in the finished part. Wait at least a minimum of 2 hours before starting the drying cycle.

d) Dewaxing / firing. All water must be removed before pouring metal to obtain proper mechanical resistance and limit defects. Note: drying time is heavily dependent on the size and number of cylinders in the oven.

Dewaxing is performed under moist conditions at 100°C, or dry conditions between 150/160°C, for 6 to 8 hours. Further dewaxing at temperatures higher than 400°C produces a perfect interior surface by eliminating the last traces of wax.

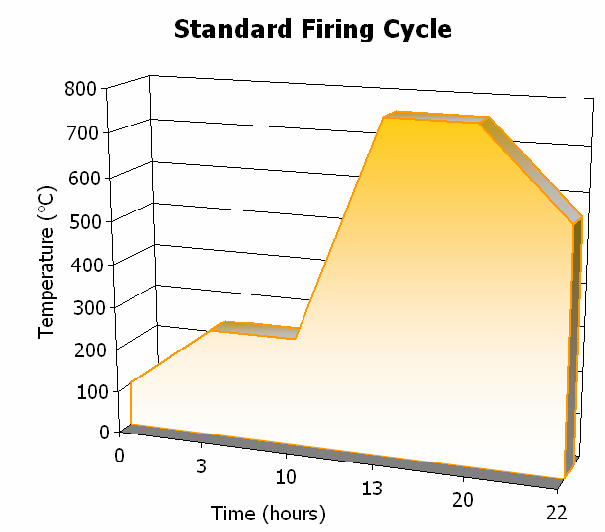

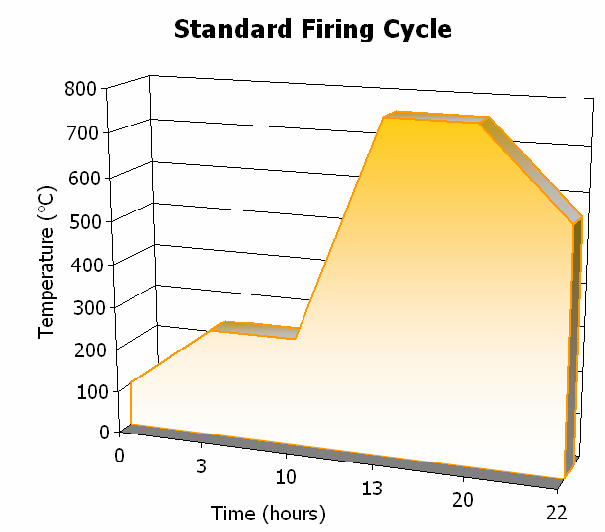

Standard firing cycle for art foundry:

Standard firing cycle for art foundry:

- place the moist mould in the oven a few hours after making it

- increase temperature to 200°C as quickly as possible

- dewax at 200°C for 2 to 8 hours depending on the size of the cylinder

- increase to 700/750°C at a rate of 100/120°C per hour

- maintain at 700/750°C for 1 hour per 1 to 2 cm of cylinder radius

- slowly decrease to casting temperature (max 70°C/hour)

e) Knocking-out. The mould is left to cool down, then shattered by immersion in water and/or by using a high pressure cleaning system. The part can then be recovered to undergo finishing steps.

Shelf Life

Do not expose to freezing and moisture, 12 months under dry condition pictures

Health and Safety

HYDRACAST™ Tradition may generate silica dust. We therefore recommend that a mask be always worn whilst working with this refractory product and to ensure that the workplace is well ventilated.

Health Warnings / H Phrases

H332 Harmful by inhalation.

H334 May cause allergy or asthma symptoms or breathing difficulties if inhaled.

Precautions / P phrases

P261 Avoid breathing dust/fume/gas/mist/vapours/spray.

Product Information

product information Hydracast Tradition

product information Hydracast Tradition

EN - Health and Safety Guidance For Using Silica Based Products.pdf

EN - Health and Safety Guidance For Using Silica Based Products.pdf

Standard firing cycle for art foundry:

Standard firing cycle for art foundry:

product information Hydracast Tradition

product information Hydracast Tradition