Polyurethane

-

Polyurethane Casting Resin (Shore D)

Fast fast-cast PU D70–D80 PU for models & parts Discover PU casting resins for precise, wear-resistant castings: fast-cast polyurethane (D70–D80),

-

Polyurethane Casting Rubber (PU Rubber)

Flexible PU rubber shore A 40–90 for molds and finished products Discover two-component polyurethane casting rubber (RTV PU rubber )

-

Polyurethane Foam

Polyurethane casting foam (2-Component PU Foam) Professional polyurethane foam (also: PU foam / PUR foam ) for hand mixing and

-

Fillers

Fillers for Polyurethane Thicken, lighten, strengthen, or create a metallic look : with our epoxy and polyurethane fillers, you can

-

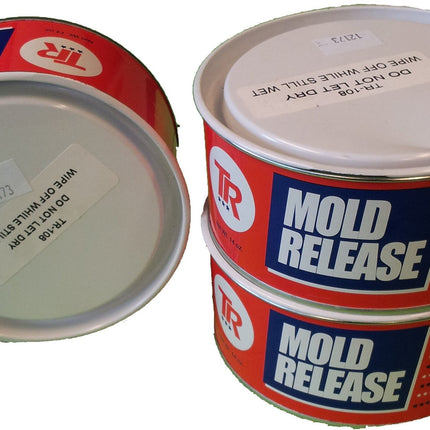

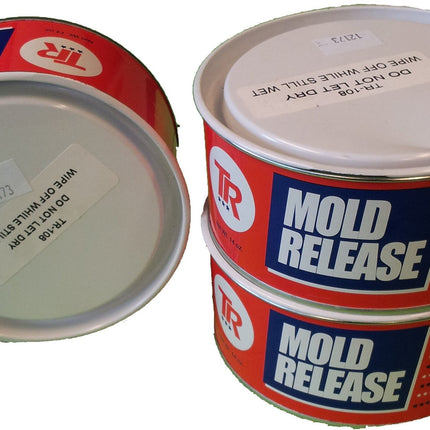

Release agents

Release agents for polyurethane, epoxy & polyester PU, epoxy, and polyester adhere strongly to many molds and substrates. Using the

-

Dyes

Epoxy & Polyurethane Dyes Transform your epoxy and PU resin projects with our professional colorant collection. Specially selected for optimal

-

PU Paints and Primers

Professional PU Paints & Primers for Industry and Maritime Discover our carefully selected range of polyurethane paints and primers from

Polyurethane (Polyurethane) for resin, foam & gel

Polyurethane (PU, PUR; EN: polyurethane, DE: polyurethane) is an extremely versatile polyurethane material that combines the best properties of rubber and plastic. From polyurethane resin for castings to polyurethane foam (PU foam) and polyurethane gel for damping and sealing: choose precisely the Shore hardness and processing method that your application requires.

⚠️ Please note (safety & regulations)

Since August 2023, polyurethane with a diisocyanate content >0.1% may only be processed in companies where employees have completed the required training. Inquire within your organization about the appropriate online course and ensure certification before starting.

Companies can register for an online training via THIS link.

You can also read more information here .

Why choose polyurethane (polyurethane material)?

- ✓ Wear-resistant & tear-resistant: up to many times more durable than conventional plastics in dynamic applications

- ✓ Wide hardness range: from soft elastomer (Shore A) to hard plastic (Shore D)

- ✓ Chemical resistance: resistant to oils, fuels and many solvents

- ✓ Precision & stability: low shrinkage, dimensionally stable; easy to process and paint after curing

- ✓ Process selection: casting, foaming, coating, bonding – including 2-component systems

Product families: polyurethane resin, foam & gel

Polyurethane Resin (PU Casting Resin)

For functional castings, molds, prototyping, and wear-resistant parts. Available as hard Shore D (structural parts) or flexible Shore A (rubbery).

- Advantages: fast curing, high impact resistance, dimensionally stable

- Applications: gears, bumpers, wheels/rollers, couplings, mold components

Polyurethane Foam / PU Foam (Polyurethane Foam)

Lightweight polyurethane foam for insulation, filler, and molded parts. Adjustable for density and cell structure.

- Advantages: low weight, cushioning, thermal insulation

- Applications: core material, protective and packaging foam, moulded foam

Polyurethane Gel (Polyurethane Gel)

Very soft, tough gel for cushioning, sealing, and vibration absorption. Ideal as a soft-touch interface or encapsulant.

- Advantages: high energy absorption, sticky/adhesive surface if desired

- Applications: pads, seals, SFX/prosthetics, protection of electronics

2-component polyurethane adhesive - professional PU adhesives

For fast and strong bonding of metals, composites, and selected plastics, there are two-component polyurethane adhesive solutions (PU 2K adhesives). They combine a short open time with high final strength and toughness.

- Strengths: quick installation, impact resistant, good peel/shear

- Applications: automotive, mechanical engineering, panel bonding, repairs

Shore hardness: choose the right PU

| Range | Characteristic | Typical Bet |

|---|---|---|

| Shore A 10–95 | Soft to semi-hard, elastic | Seals, elastic parts, damping |

| Shore D 40–85 | Hard and stiff, plastic-like | Structural components, wear-resistant parts |

Polyurethane applications

- Industrial : conveyor rollers, bearings, guides, wear parts

- → Automotive: mufflers, bumpers, interior parts

- → Composites & Moulds: flexible/rigid moulds, core and edge reinforcements

- → Construction & insulation: PU foam (polyurethane foam) for thermal/acoustic functions

- → Prototyping: functional models, end-use parts

FAQ - Polyurethane definition & frequently asked questions

What is polyurethane? (polyurethane definition)

Polyurethane is a family of polymers formed by the reaction of polyols with (di)isocyanates. Depending on the formulation, polyurethane resin, polyurethane foam, or polyurethane gel are created with varying hardness and properties.

What is the difference between PU foam and PU resin?

PU foam (polyurethane foam) is a low-density, cellular structure used for insulation/filling. PU resin is solid and is used for sturdy castings and components.

Do I need training to process PU?

Yes, training is mandatory for systems containing >0.1% diisocyanate. Ensure employees are certified before working with PU.

Advice & order

Looking for polyurethane resin, polyurethane foam, polyurethane gel, or a two-component polyurethane adhesive? We'll help you choose the right polyurethane for your process and Shore range.